Understanding the Importance of the 9007BSPP to NPTF Fitting in Plumbing and Hydraulic Systems

In the realm of plumbing and hydraulic systems, ensuring secure and leak-proof connections is paramount. One critical component in achieving this is the fitting that bridges the gap between different thread standards. Among the various types of fittings, the 9007BSPP to NPTF fitting stands out as an essential tool for professionals navigating systems that utilize the British Standard Pipe Parallel (BSPP) and National Pipe Tapered Fuel (NPTF) thread standards. This article delves into the significance of these fittings, their applications, and how they facilitate smooth operations across diverse industries.

What is a BSPP Fitting?

BSPP, or British Standard Pipe Parallel, is a type of threaded fitting that originated in the UK. It is widely used across Europe and various other regions. Unlike tapered threads, BSPP fittings feature straight threads, meaning they maintain a consistent diameter along the length of the fitting. This characteristic differentiates them from their counterparts, such as BSPT (British Standard Pipe Tapered) and NPTF fittings.

In BSPP systems, a tight seal is typically achieved using additional sealing materials like O-rings or washers, rather than solely relying on the threads for sealing. This makes BSPP fittings versatile and adaptable to various applications, particularly where flexibility in sealing materials is required.

The 9007BSPP to NPTF fitting serves a critical function by connecting BSPP components to NPTF systems. Without this fitting, it would be challenging to establish secure connections between systems that employ different thread designs and sealing methods.

What is an NPTF Fitting?

NPTF, or National Pipe Tapered Fuel, is a thread standard commonly used in the United States. NPTF fittings feature tapered threads, which means the diameter decreases along the length of the fitting. A key feature of NPTF fittings is their ability to create a dry seal. This sealing method relies on the compression of the threads themselves, forming a tight, leak-proof connection without the need for additional sealing materials.

The 9007BSPP to NPTF fitting acts as an adapter that allows for the seamless integration of BSPP-threaded components into NPTF systems. This adaptability is essential in various applications, particularly in hydraulic systems where reliable connections are crucial.

Why Thread Compatibility Matters

Thread compatibility is vital to the overall functionality and safety of hydraulic and plumbing systems. Using incorrect fittings can result in leaks, equipment failure, and potential safety hazards. By employing a 9007BSPP to NPTF fitting, professionals can ensure that British BSPP components can safely connect with American NPTF components, facilitating seamless integration between these two thread standards.

Ensuring thread compatibility not only protects the integrity of the system but also minimizes the risk of costly downtime and repairs. For instance, a malfunctioning connection could lead to system failures that halt production in manufacturing settings, emphasizing the importance of using the correct fittings.

The Role of the 9007BSPP to NPTF Fitting

The 9007BSPP to NPTF fitting functions as a crucial adapter, enabling the connection of components across systems that employ different thread standards. This fitting is particularly valuable in scenarios where components from various manufacturers must be integrated into a single system.

Without the 9007BSPP to NPTF fitting, connecting components from different thread standards would present significant challenges. The fitting acts as a bridge, simplifying the installation process and ensuring that systems operate efficiently and effectively.

Common Applications

You will find 9007BSPP to NPTF fittings in several industries, including:

- Manufacturing: Hydraulic systems used in machinery often require these fittings to connect components from different manufacturers or regions.

- Aerospace: In aerospace applications, where reliability and precision are paramount, ensuring the correct thread compatibility is critical for safety.

- Automotive: The automotive industry often utilizes hydraulic and pneumatic systems that require seamless connections between different thread standards.

- Global Trade: As international trade continues to expand, products from Europe and the United States frequently need to be integrated, making the 9007BSPP to NPTF fitting an indispensable tool.

The fitting’s versatility extends to hydraulic machinery, fuel systems, and even some plumbing setups, underscoring its importance in maintaining system integrity and efficiency.

How the 9007BSPP to NPTF Fitting Works

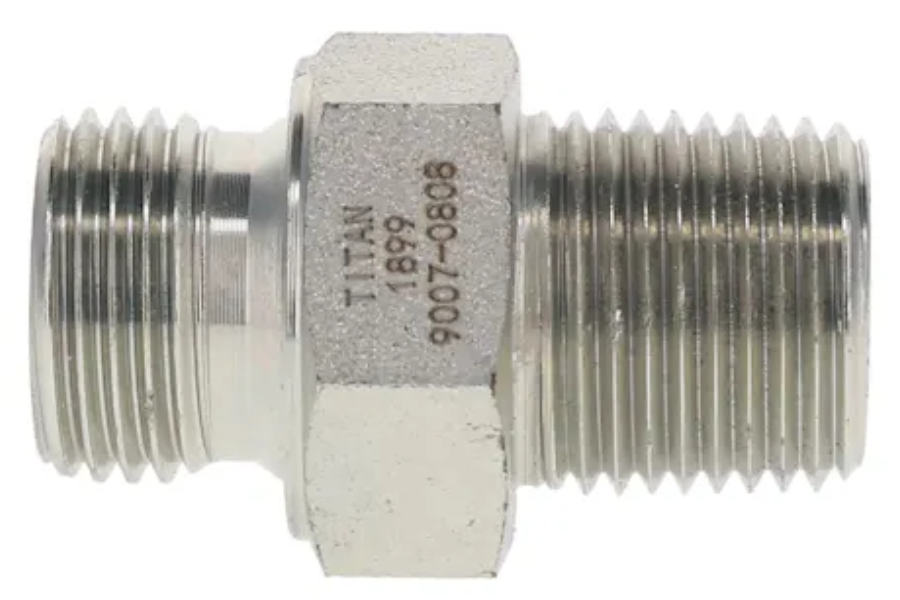

The 9007BSPP to NPTF fitting is designed with BSPP threads on one end and NPTF threads on the other. This configuration allows for a smooth connection between the two different thread types within the same system.

During installation, it is essential to ensure that the BSPP end utilizes the necessary sealing materials, such as O-rings or washers, to maintain a leak-proof seal. In contrast, the NPTF end forms a dry seal by compressing the tapered threads upon tightening. This dual-sealing approach effectively mitigates the risk of leaks, which is crucial for the functionality of hydraulic and plumbing systems.

Importance of 9007BSPP to NPTF Fittings in Global Operations

In today’s globalized market, equipment manufactured in one country is often exported to another. Different countries adhere to distinct thread standards, which can complicate the integration of machinery. For example, a machine built in Europe may utilize BSPP threads, while the infrastructure in the United States predominantly employs NPTF fittings.

The 9007BSPP to NPTF fitting eliminates the need for costly modifications or replacement parts, ensuring that equipment operates seamlessly across borders. This adaptability significantly benefits companies, allowing them to save both time and money. The fitting’s role in facilitating international trade is particularly crucial as industries strive for greater efficiency and collaboration.

Common Challenges with Thread Conversion

While the 9007BSPP to NPTF fitting provides a convenient solution for thread conversion, it does come with its own set of challenges. Some common issues include:

- Misalignment During Installation: If not installed correctly, misalignment can lead to leaks or system failure. Careful attention during installation is necessary to ensure proper alignment.

- Incorrect Sealing Materials: The wrong type of O-ring or sealant used on the BSPP end can compromise the connection, leading to potential failures. It is vital to select sealing materials compatible with the specific application.

Professionals must be aware of these challenges and implement best practices to ensure successful installations.

Materials Used in 9007BSPP to NPTF Fittings

The materials used in 9007BSPP to NPTF fittings play a significant role in their performance and durability. Common materials include:

- Stainless Steel: Known for its corrosion resistance, stainless steel is often preferred in harsh environments, such as marine or chemical applications. Its durability ensures that the fitting can withstand high pressures and maintain integrity over time.

- Brass: Brass fittings are suitable for less demanding conditions and are often used in plumbing applications. They offer good corrosion resistance and are easier to machine than stainless steel.

- Carbon Steel: This material is commonly used in applications requiring strength and durability. However, it may be less resistant to corrosion than stainless steel or brass, making it more suitable for indoor applications.

The choice of material depends on the specific application and environmental factors. Selecting the appropriate material ensures that the fitting can withstand the conditions it will face.

Selecting the Right 9007BSPP to NPTF Fitting

When choosing a 9007BSPP to NPTF fitting, several factors must be considered to ensure optimal performance:

- Pressure Rating: Ensure that the fitting is rated for the pressure conditions it will encounter. Using a fitting with a lower pressure rating than required can lead to failure.

- Temperature Range: The fitting should be suitable for the temperature conditions of the application. Extreme temperatures can affect the performance and lifespan of the fitting.

- Material Compatibility: Choose a fitting made from materials compatible with the fluids or gases being transported. This compatibility is crucial for preventing chemical reactions that could compromise the integrity of the fitting.

- Size Matching: Ensure that the fitting size matches the components being connected. Using fittings that are too large or too small can result in leaks or operational failures.

By considering these factors, professionals can select the right fitting for their specific needs, ensuring that systems operate efficiently and safely.

Conclusion

The 9007BSPP to NPTF fitting is a vital component in industries that require integration between British and American thread standards. Whether in hydraulic systems, plumbing, or fuel lines, this fitting provides a reliable and efficient solution for connecting incompatible threads. By ensuring proper selection, installation, and maintenance of these fittings, professionals can guarantee the success and safety of their operations.

With the right materials and techniques, 9007BSPP to NPTF fittings help ensure that systems run smoothly and efficiently, regardless of their origin. Understanding the differences between thread types and the importance of compatibility is essential for professionals dealing with piping systems, allowing them to make informed decisions and avoid costly errors. In a world increasingly driven by globalization, these fittings play an indispensable.

Delve into fascinating tales and profiles of your beloved stars at leomorg.org.